Disgorging - Dosing

Manual disgorging - dosing, model ALPHA

Manual machine for the disgorging, dosing and topping up of sparkling wine bottles up to 100-150 bottles per hour.

- Adjustable disgorging mouth in order to work “a la volée” or in cold with neck freezer.

- Includes a liquor tank with inert gas inlet and manometer to adjust the pressure.

- Frontal arm to work any type of bottle between 37,5 cl and 150 cl.

- Maximum liqueur dosage of 6 cl with manual lever.

- Topping up system through an upper wine tank of 5 liters.

- Topping up is also made through a manual lever until reaching the required level of wine.

- Machine totally built in stainless steel.

- The only requirement is inert gas supply in order to pressurize the liqueur.

Semi-automatic disgorging dosing, model DELTA

Semi-automatic disgorging, dosing and topping up machine with manual loading and unloading for an output up to 650 bottles per hour.

- Equipped with an automatic disgorging system designed to remove caps “a la volee” or working with a neck freezer. Includes a device tthat controls that the crown cap has been correcty removed.

- An adjustable nozzle for the partial emptying.

- A liqueur doser with a maximum of 6 cl.

- An adjustable nozzle for topping up.

- Cleaning system of the whole wine circuits of the machine.

- Manufactured in stainless steel.

- Designed to work with formats of 37,5 cl, 75cl and 150 cl (maximum diameter: 115 mm)

Possibility to manufacture special versions for bottles with a diameter up to 140 mm.

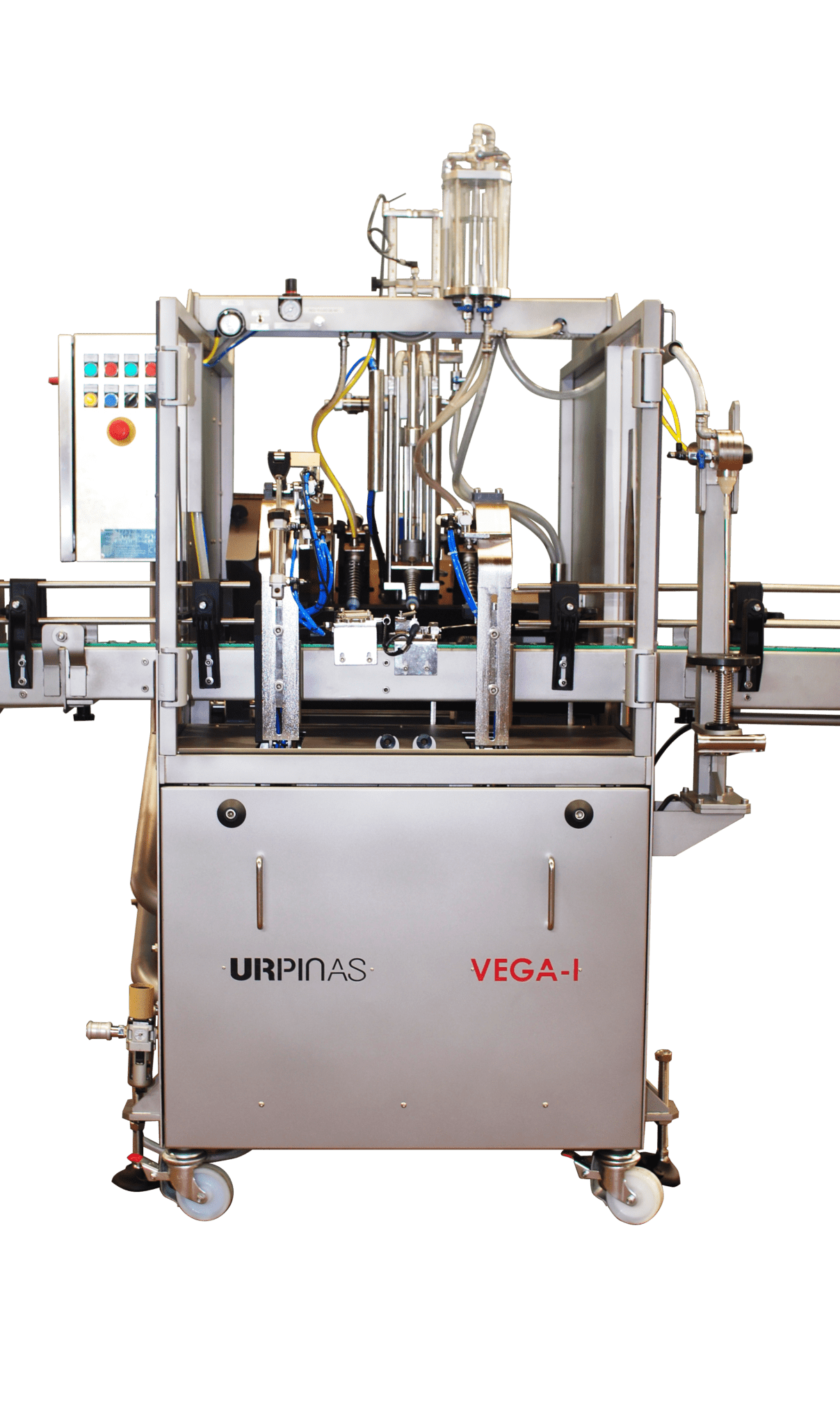

Automatic disgorging and dosing, models VEGA

Linear disgorging, dosing and topping up machine with automatic loading and unloading for an output of 600 and 1,000 bottles per hour.

- Equipped with an entrance arm which tilts 1 or 2 bottles and disgorges the bottles. Includes a device tthat controls that the crown cap has been correcty removed.

- 1-2 partial emptying nozzles depending on the model.

- 1-2 liqueur dosers depending on the model.

- 1-2 topping up nozzles depending on the model.

- Cleaning system of the whole wine circuits.

- Manufactured in stainless steel.

- Designed to work with formats from 37,5 cl to 150 cl (maximum diameter: 115 mm)

model VEGA-I: Cycles of 1 bottle

model VEGA-II: Cycles of 2 bottles

Automatic rotary disgorging and dosing monoblocks, models DVDR

Rotary disgorging and dosing monoblocks for an output between 1,000 and 4,500 bottles per hour.

- The bottles enter the disgorging station through a worm and a star places them in the 4 or 6 disgorging arms depending on the model.

- In a second step, the bottles enter the dosing station through a worm and a star places them under the partial emptying, liquor dosing and topping up nozzles with 6-9-12 arms depending on the model.

- On the first lap, bottles are placed vertically under a partial emptying nozzle.

- On the second lap, the bottle is tilted at 60º and hermetically closed under a liqueur doser for a maximum of 6 cl.

- On the third lap, bottles are placed vertically under a topping up nozzle.

- Structure built in stainless steel.

- Cleaning system with water sprays.

- LED light inside the machine.

- Designed to work with formats between 37.5 cl and 150 cl.

Automatic rotary disgorging, models D

Rotary disgorging machine with automatic loading and unloading for an output between 2,000 and 18,000 bottles per hour.

- The bottles enter the machine through a worm and a star places them under the rotary central disgorging station with 4-10-24 or 36 disgorging arms depending on the model.

- The bottles are handled with a plastic fork in order not too break the neck.

- Each arm is equipped with an adjustable disgorging nail.

- Disgorging leftovers are ejected through a stainless steel tube with a Venturi air device.

- Structure built in stainless steel.

- Cleaning system with water sprays.

- LED light inside the machine.

- Designed to work with formats between 37.5 cl and 150 cl.

Automatic rotary dosing machines, models VDR

Rotary dosing machines with automatic loading and unloading for an output between 2,000 and 4,500 bottles/hour.

- The bottles enter the machine through a worm and a star places them under the rotary central dosing station with 6-9-12 disgorging arms depending on the model.

- On the first lap, bottles are placed vertically under a partial emptying nozzle.

- On the second lap, the bottle is tilted at 60º and hermetically closed under a liqueur doser for a maximum of 6 cl.

- On the third lap, bottles are placed vertically under a topping up nozzle.

- Structure built in stainless steel.

- Cleaning system through water sprays.

- LED light inside the machine.

- Designed to work with bottles of 37,5 cl. 75 cl and 150 cl.

Automatic liqueur dosing with 3 stations, models M

Liqueur dosing machines for outputs between 5,000 and 12,000 bottles/hour.

- Monoblocks of 3 rotary stations including a partial emptying station, a liqueur dosing station and a topping up station.

- Stations equipped with 18-24-32-36 arms depending on the model.

- The bottles are handled with a plastic plier in order to protect the neck of the bottle.

- Structure built in stainless steel.

- Cleaning system through water sprays.

- LED light inside the machine.

- Designed to work with bottles of 37,5 cl and 75cl.

NEWS SPARKLING

Just one click away from all the news… if you want to be informed of our last news, you just need to subscribe to our SparklingNewsletter.

Contact

Riera de Palau, 36 Nave 3

Sant Andreu de la Barca

08740 Barcelona- Spain

Sant Andreu de la Barca

08740 Barcelona- Spain

+34 93 015 36 63

sales@sparklingequipment.com